The marine industry plays a vital role in global trade and transportation. To keep up with this demand, the industry must find innovative ways to improve efficiency and prioritise safety. With increasing pressure to meet these challenges, the need for innovation has become more urgent than ever and new marine PPE and safety equipment won’t be far behind.

The use of artificial intelligence within the marine and shipping industry may surprise you. One of the most promising applications is through route optimisation. AI can be essential in helping ships navigate the most efficient and cost-effective routes. This is particularly important in the face of rising fuel costs, as optimised routes can reduce fuel consumption and transportation costs.

Autonomous Vessels:

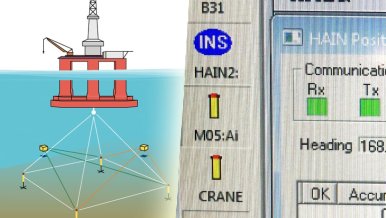

AI is used in the development of autonomous or semi-autonomous vessels. These vessels can navigate, avoid obstacles, and make decisions based on real-time data using AI algorithms, sensors, and communication systems.

Predictive Maintenance:

AI helps in predicting equipment failures and maintenance needs by analyzing data from various sensors. This proactive approach reduces downtime and enhances the reliability of marine systems.

Route Optimization:

AI algorithms analyze historical and real-time data, such as weather conditions, sea currents, and vessel performance, to optimize navigation routes. This improves fuel efficiency, reduces emissions, and enhances overall operational efficiency.

Collision Avoidance:

AI-based collision avoidance systems use data from radar, sonar, and other sensors to detect potential collisions and take corrective actions, such as altering course or adjusting speed.

Weather Forecasting and Risk Management:

AI is used to process large datasets and improve the accuracy of weather forecasting, helping vessels plan routes to avoid adverse conditions. AI also contributes to risk assessment and management in the marine industry.

Supply Chain Optimization:

AI is employed to optimize supply chain logistics, including cargo scheduling, port operations, and inventory management. This ensures timely and cost-effective transportation of goods.

Environmental Monitoring:

AI technologies, including remote sensing and image analysis, are used for monitoring and managing environmental impacts in marine ecosystems. This includes detecting oil spills, monitoring water quality, and assessing the health of marine life.

Energy Efficiency:

AI helps in optimizing energy consumption on vessels by analyzing and adjusting engine performance, monitoring fuel usage, and recommending energy-efficient practices.

Security and Surveillance:

AI-powered surveillance systems enhance security in ports and on vessels. These systems can identify and alert authorities to suspicious activities, improving overall maritime security.

Data Analytics for Decision-Making:

AI facilitates the analysis of vast amounts of data collected from sensors, satellite imagery, and other sources. This information aids decision-making processes, enabling operators to make informed choices for vessel operations, maintenance, and business strategies.

The integration of AI in the marine industry is expected to continue evolving, leading to increased automation, improved safety, and enhanced operational efficiency. As technology advances, new applications and solutions will likely emerge, further transforming the maritime sector.

In the near future artificial intelligence can be a very good assistant for seafarers, but you should not rely on it 100%, because the human factor is the strongest, and in some situations can find a quick way out, in which the artificial intelligence can fail in the system, for example due to the work on a pattern or lack of communication.

While artificial intelligence (AI) has the potential to play a significant role in the maritime domain, fully replacing human beings is unlikely in the foreseeable future. The maritime industry involves complex and dynamic situations that require human expertise, decision-making, and adaptability.

Here are a few reasons why complete replacement is unlikely:

Complex Decision-Making: The maritime environment is unpredictable and often involves complex decision-making processes that require human intuition, experience, and ethical considerations. AI may assist in decision support systems, but the final decisions are likely to remain in human hands.

Regulatory and Ethical Considerations: The maritime industry is subject to strict regulations and international standards. Fully autonomous vessels would need to comply with these regulations, and issues such as liability, safety, and ethical concerns would need to be addressed before widespread adoption.

Emergency Situations: Humans are better equipped to handle unexpected and emergency situations at sea. The ability to adapt to unforeseen events, make split-second decisions, and respond to emergencies with empathy is currently beyond the capabilities of AI.

Maintenance and Repairs: Vessels require maintenance, repairs, and troubleshooting, tasks that often require a hands-on approach. While AI can assist with predictive maintenance, there will still be a need for engineers.

Human Interaction: The maritime industry involves interactions with various stakeholders, including crew members, port authorities, and other vessels. Effective communication and collaboration, which involve emotional intelligence and cultural understanding, are areas where human presence is crucial.

Public Perception and Trust: Acceptance of fully autonomous vessels may face challenges in gaining the trust of the public and maritime stakeholders. There will likely be a gradual transition, with a focus on human oversight and collaboration with AI systems.

AI can certainly enhance efficiency, safety, and decision support in the maritime domain, a complete replacement of humans by AI in this field is not currently feasible due to the complexity of the tasks and the need for human skills in certain critical situations. The future is likely to involve increased integration of AI technologies to augment human capabilities rather than outright replacement.