The pilot ladder is a specialized rope ladder employed for the boarding and disembarking of pilots and crew members during various ship operations. The steps of the ladder are made of hardwood except the lower four steps are made of rubber.

The safety of pilot ladder usage relies on a complex chain of regulations, recommendations, industry standards, and procedures. Should any of these elements fail, the entire safety system could collapse, potentially resulting in severe and fatal consequences.

Given the unique characteristics of each vessel's construction, the correct method for rigging the ladder can vary significantly for each ship.

A Matter of Safety.

The safety of all pilots and crew members hinges on maintaining proper procedures when it comes to pilot ladder steps. The goal is for everyone to return home safely. Pilots come aboard vessels to support the ship's crew during critical and potentially hazardous navigation phases. Tragically, there have been instances where pilots have lost their lives or suffered injuries due to accidents during boarding and disembarkation procedures.

To prevent such incidents, it is imperative that the ship's crew and officers undergo training on the correct installation of a compliant pilot ladder and the rigging thereof, ensuring that they meet established standards and requirements.

Convention compliance:

- SOLAS Ch v Regulation 23;

- IMO resolution A. 1045 (27);

- IMO MSC 1428;

- IMO MSC 1495;

- ISM chapter 10;

- ISO 799-1.

Certificate and Marking:

Each pilot ladder should have a certificate in accordance with SOLAS Ch V Reg 23.2.1 and ISO 799:2004 standard.

Certificate contents:

- Name of the manufacturer;

- certifying body;

- SOLAS approval;

- type pilot ladder or embarkation ladder;

- production date;

- onboard date (must be entered by ship staff).

Certificate and Expiry Date:

- Pilot ladders made to ISO 799 standards must undergo a strength test every 30 months, or the certificate must clearly state the expiration date.

Identification:

- Every pilot ladder used for pilot transfers must bear unique identification tags or markings to facilitate surveys. Tags must be affixed at the bottom of the first step and the last spreader, containing essential information.

Hull Marking:

- Recommended hull markings consist of white over red, with a width of 0.5 meters. The top two meters should be white, while the bottom two meters should be red. The positioning of the white mark's bottom indicates its proper alignment.

Ladder Design:

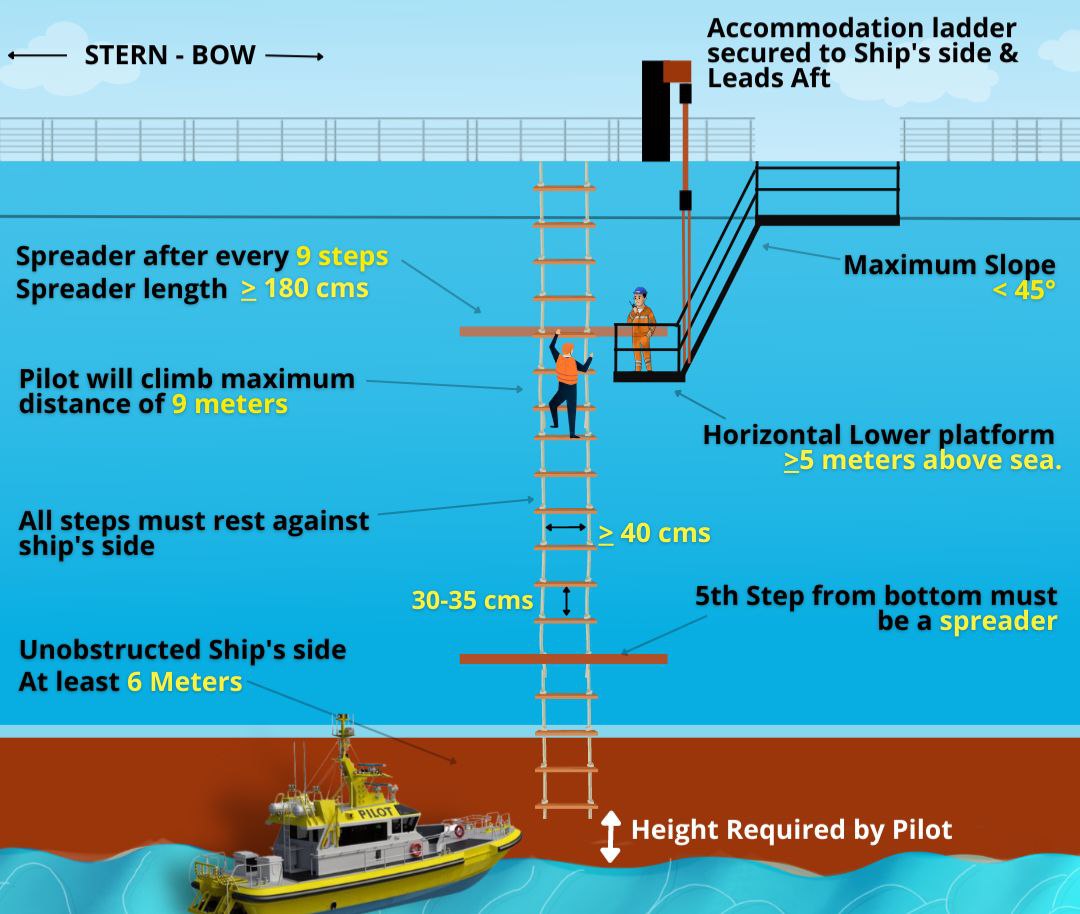

- The 9-meter freeboard step must be constructed as a single piece of hardwood without paint or varnish to prevent slipperiness. The lower four steps must be made of rubber.

- Step dimensions should be 400mm between side ropes, 115mm in width, and 25mm in thickness, with equal spacing between 310mm to 350mm.

- If the ladder has more than five steps, it should include a spreader of 180cm length. The maximum number of steps between spreaders is nine, with the fifth step serving as a spreader.

- All steps must remain horizontal and have metal tags at the bottom of the first step and last spreader. The replacement of steps should not exceed two in number.

Side Ropes:

- Two uncovered ropes, each not less than 18mm in diameter, should run continuously on each side, made of manila rope or equivalent with a breaking strength of 24 kg to kN.

- Side ropes should not form a loop at the bottom, and man ropes on both sides of the pilot ladder must be rigged upon the request of the pilot only.

- A 28mm to 32mm diameter retrieval line is optional but, if fixed, must be positioned above the last spreader and led forward.

Ladder Mounting:

- Both ladders must comply with an open-bottom model and should be securely clamped. The length of side rope below the final steps should not be less than 5cm, with a diameter not less than 32mm.

- The distance between two stanchions should be within the range of 0.7 to 0.8 meters, with stanchion height at 1.2 meters above the bulwark.

- Stanchions and rigid handrails should be present on both sides of the ladder and platform, but if hand ropes are used, they should be taut and properly secured.

Pilot Ladder Winch Reel:

- Pilot ladder winch reels offer an efficient means of storing and moving the ladder. These are usually installed on the ship's upper main deck or at side openings, such as side doors, gangway locations, or bunkering points.

- Winch reels on the upper deck may result in very long pilot ladders, embarkation platforms, or trapdoors.

Minimum Climbing Height:

- The minimum climbing height for a pilot ladder ranges from 1.5 meters to 9 meters. This range is chosen because after three steps, there may be nothing to hold onto, and falling from heights greater than nine meters poses significant risks.

Gangway Platform:

- The horizontal platform of a gangway should be no less than five meters above water level. During combination rigging, the pilot ladder must extend 2 meters above the platform.

- The pilot ladder must be secured to the hull at a distance of not less than 1.5 meters from the gangway platform.

- The horizontal distance between the gangway platform and the pilot ladder should be between 0.1 to 2 meters, and the ladder should not be tied to the gangway.

- The angle of the gangway should be less than 45 degrees.